We create intelligent automation and orchestration for maximum efficiency in your processes.

Unlock Untapped Opportunities in Your Business Processes

The pilot project serves as your entry point into transparent and scalable business process automation and orchestration.

The Process Factory offers a scalable solution for the continuous implementation and optimization of process automations.

Delegate the Migration to Experts

Unlock Untapped Opportunities in Your Business Processes

In our potential analysis, we examine a selection of your existing processes to uncover hidden opportunities for efficiency improvements and optimization. Our approach aims to provide you with a clear roadmap to enhance your operational performance.

Identify critical bottlenecks and inefficiencies that impact your productivity and cost structure.

Identify Improvement Potential

With the help of the potential analysis and the associated ROI analysis, we determine your short-, medium-, and long-term improvement potential

Our experts calculate the return on investment of your potential process improvements to ensure that your investments deliver maximum returns.

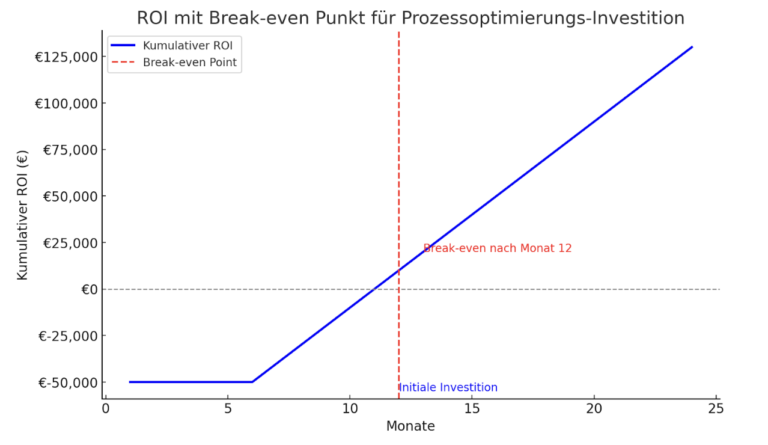

ROI Chart with Break-even Point

Our ROI chart illustrates the break-even point of your automation investment, highlighting the increasing savings and profits from that point onward.

Leverage our in-depth analyses and recommendations as the foundation for your strategic decisions in process optimization.

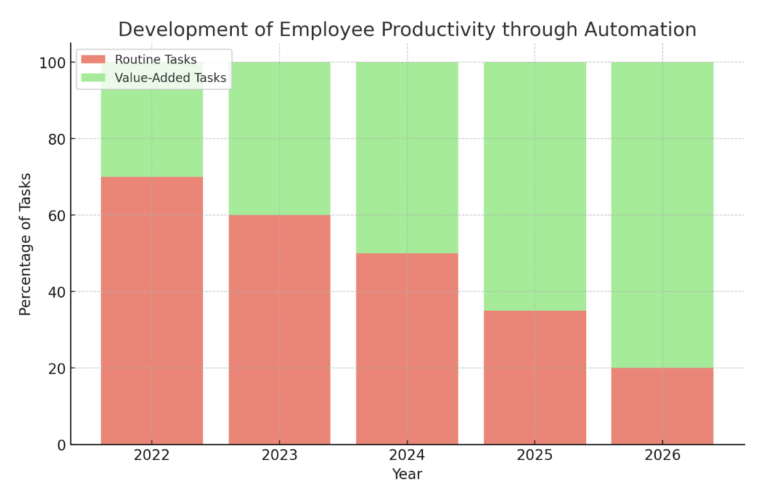

Increase in Employee Productivity

Our employee productivity chart illustrates how automation creates room for higher-value tasks. It highlights the shift from routine work to value-added activities and demonstrates the long-term productivity growth.

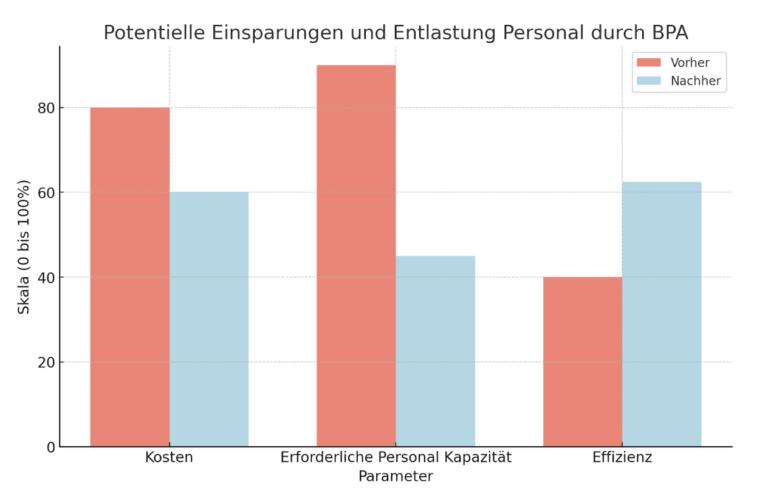

Cost Savings Along with Employee Relief

Our chart provides a clear view: high costs and manual labor before automation, followed by reduced costs and increased efficiency afterward. This allows you to conserve resources and be better prepared for demographic challenges.

Gain detailed insights into the current costs of your processes and the potential savings through automation and optimization.

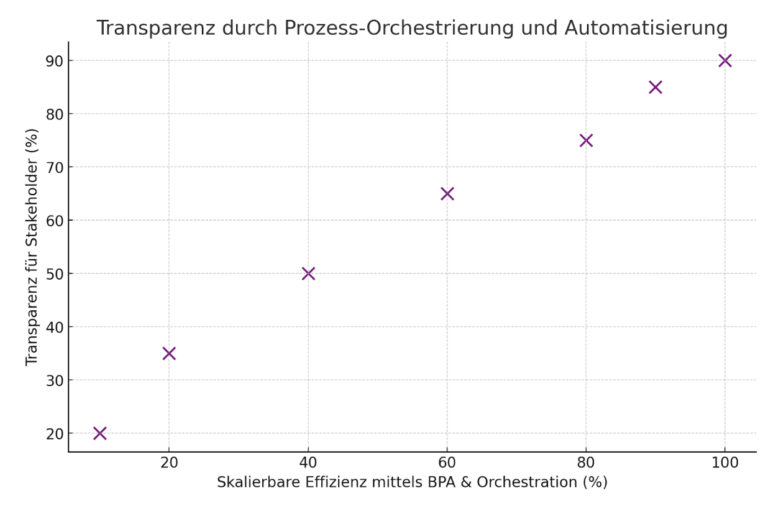

Transparency for Your Business Through Process Orchestration & Automation

Professional process orchestration provides you with both an overview and the necessary details of your processes. Combined with automation, we establish the foundation for efficiently scaling and evolving your process landscape.

The pilot project serves as your entry point into transparent and scalable business process automation and orchestration.

It is designed to provide concrete insights and achieve initial results, laying the foundation for long-term, sustainable scaling.

With our structured approach, we ensure that your optimization potentials are identified and implemented in a targeted manner.

We identify improvement potentials to reduce costs and increase employee productivity. We model the process using BPMN 2.0, making it both visually comprehensible and machine-readable.

We evaluate improvement potentials both qualitatively and quantitatively to provide a solid foundation for your decisions.

We determine how much of the process can be automated to effectively manage cost reductions and productivity increases.

Modeling with BPMN 2.0 ensures that your process is not only comprehensible and machine-readable but also adheres to industry-recognized standards.

Our ROI Calculation Focuses on the Following Key Areas

Conduct a comprehensive cost-benefit analysis of the first selected process to thoroughly evaluate the economic value of the pilot project.

Identification of all incurred costs, including implementation, licensing, maintenance, and operational costs. These serve as the foundation for a comprehensive analysis of resource utilization.

Analysis of expected savings, employee relief, and efficiency improvements, such as reducing manual tasks, lowering error rates, and increasing productivity.

Presentation of the timeframe in which the break-even point will be reached, along with a forecast of how cost savings will evolve over time. This aids in decision-making for long-term planning.

Planning and practical implementation of the first selected process.

Deployment of the automated process in production with initial optimizations. The expected efficiency improvements are validated.

After the deployment of the automated process, the procedure is repeated for additional processes.

The Process Factory takes care of all steps for you, from identifying the suitable process candidate to delivering a fully automated process to your team.

This allows you to focus on your core business objectives while we ensure seamless automation.

As input, you provide us with a process candidate that is to be optimized and automated.

The fully orchestrated process is ready for use and seamlessly integrated into your system landscape.

Through standardized, agile approaches and proven methods, processes can be automated faster and more efficiently.

After successfully automating one process, the approach can be easily extended to additional processes.

Minimized manual interventions and reduced errors lead to improved process quality and enhanced efficiency.

The Process Factory can adapt to changing requirements and continuously incorporate new optimizations.

Since automation is fully handled by our Process Factory, you don’t need to allocate your own resources. This allows your internal team to focus on strategically important tasks and projects, while we implement the automation efficiently and seamlessly.

We analyze the selected process and model it in a way that it is optimized and machine-readable.

A comprehensive cost-benefit analysis shows you the economic value of automation.

The process is orchestrated, automated, and prepared for production use using state-of-the-art methods.

We test the automated process in your environment to ensure it functions seamlessly.

The process goes live, and you immediately benefit from the optimized workflows and efficiency gains.

At JIT, we have been using Camunda 7 in many different projects since 2014, and since 2023, we have been using Camunda 8 for new projects. Since 2023, we have successfully completed numerous migration projects with various conditions and objectives.

Dank unserer langjährigen Erfahrung und unserem klaren Fokus auf Business Process Automatisierung & Orchestrierung sind wir der perfekte Partner für deine Camunda 7-zu-8-Migration.

We offer this module to you at a fixed price, so you have full cost control from the start.

As a foundation, we follow the steps recommended by the product manufacturer:

• Evaluate

• Define Scope

• Plan

• Platform Setup

• Migrate

• Operate

We optimize these steps with insights gained from our countless projects.

We clarify which processes and functionalities from Camunda 7 need to be migrated to Camunda 8.

Compatibility Check: Depending on how you have implemented Camunda 7, we analyze the differences between the two versions accordingly.

We distinguish between the following strategies:

Wir identifizieren potenzielle Herausforderungen und planen Maßnahmen zur Risikominderung.

We offer this module to you at a fixed price, so you have full cost control from the start.

Camunda 8 is based on Zeebe, a distributed cloud-native architecture that enables high throughput and scalability, while Camunda 7 can be used as an embedded engine.

We check whether the current BPMN models and process definitions are fully compatible with Camunda 8 and make adjustments if necessary.

Wir machen dich hands-on mit neuen Features vertraut, z. B. Event-Driven Architecture und verteilte Skalierbarkeit.

We offer this module to you at a fixed price, so you have full cost control from the start.

We ensure that all BPMN models are optimized for execution on Camunda 8. Some modeling elements may be interpreted differently.

We adjust your code to the Zeebe API and use tools like the Java Delegate Adapter when necessary. If required, we replace the embedded engine with Zeebe client integration for your project.

We provide a Camunda 8 test environment and conduct initial integration and load tests to validate functionality.

We gradually migrate the processes from Camunda 7 to Camunda 8 to minimize risks.

Using appropriate migration tools, we transfer ongoing process instances from Camunda 7 to Camunda 8. Alternatively, we let the ongoing instances finish in Camunda 7 and start new instances directly in Camunda 8.

We export all historical data and process information from Camunda 7. Since Camunda 8 does not use an RDBMS, a data transformation is required for consistent historization.

Together, we will decide whether and how historical process data from Camunda 7 and Camunda 8 should be historized or alternatively archived.

Minimized manual interventions and reduced errors lead to improved process quality and enhanced efficiency.

The Process Factory can adapt to changing requirements and continuously incorporate new optimizations.

We offer this module to you at a fixed price, so you have full cost control from the start.

We establish a CoE that serves as a center of excellence for process automation with Camunda 8, providing resources and support for your organization.

We establish a CoP where your IT team can quickly and efficiently build and share internal knowledge to implement process orchestration efficiently with Camunda 8.

We carry out the installation in multiple phases together with your team in the production environment to ensure system stability and identify potential errors early on.

We monitor the process execution together with you and analyze performance data to increase efficiency and make adjustments as needed.

We collect feedback from users and teams to make improvements and optimize the system.

JIT – Die #Prozessmacher

Discuss the key aspects of your digital transformation!

Copyright © 2024